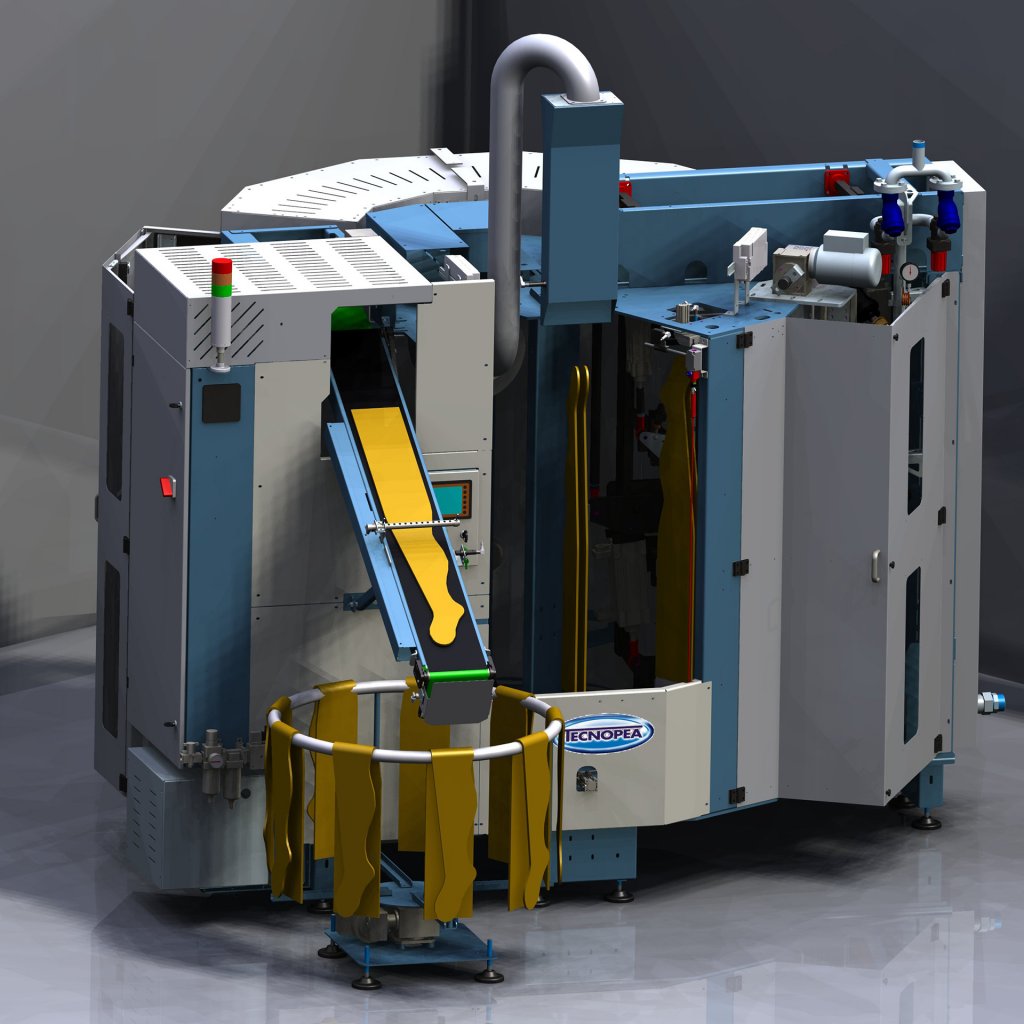

SD15

Stockings steam boarding machine.

Steam boarding machine for pantyhoses, stockings and knee-highs.

SD15

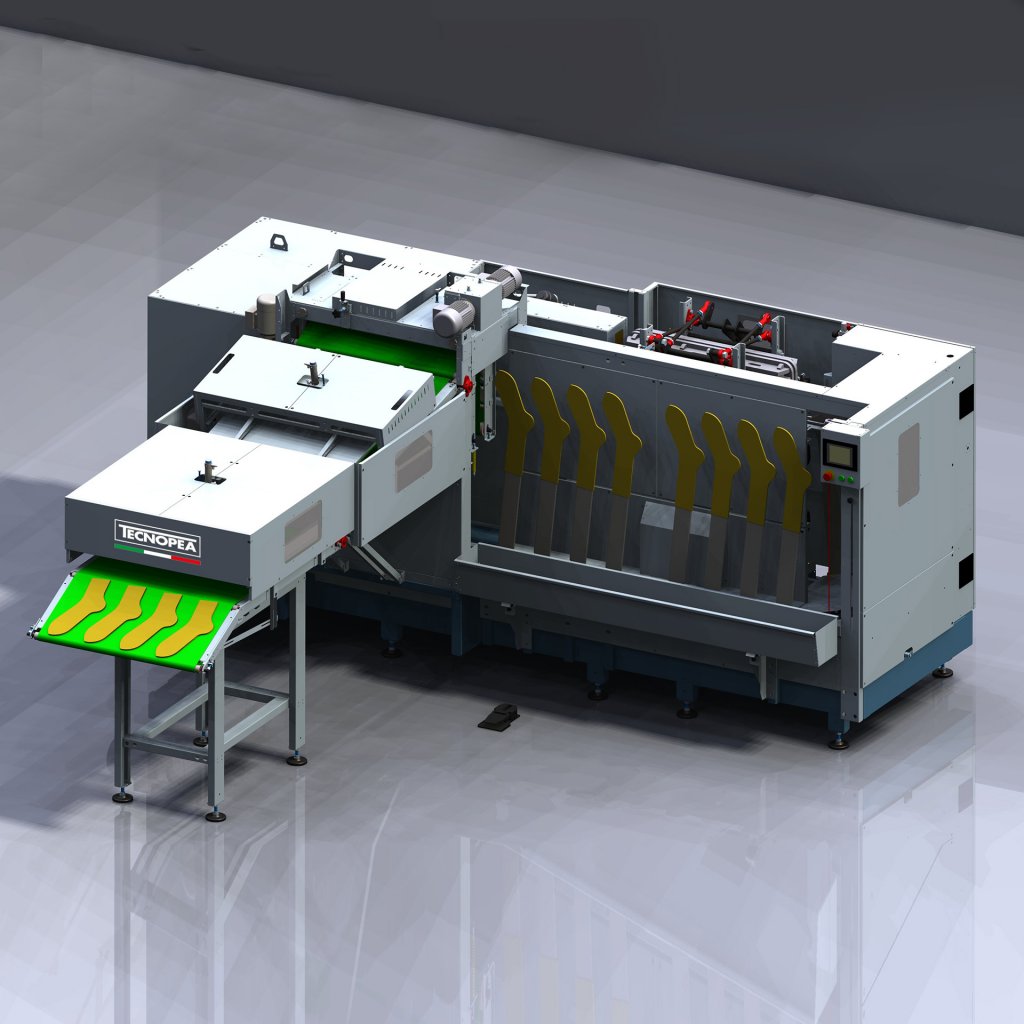

The loading of the pantyhose is on transparent forms for control, then the transfer of stockings from the transparent forms , is performed by a robot. The 15 pairs of forms are in a flanked position during all stages of processing. The pairs of shapes are “ book closed" only after the drying phase and the stockings are doffed by a belt stripping device , presenting 'perfectly matched paired and stacked on the carousel or transferred to subsequent modules to be packed.

Steam boarding machine for pantyhoses, stockings and knee-highs.

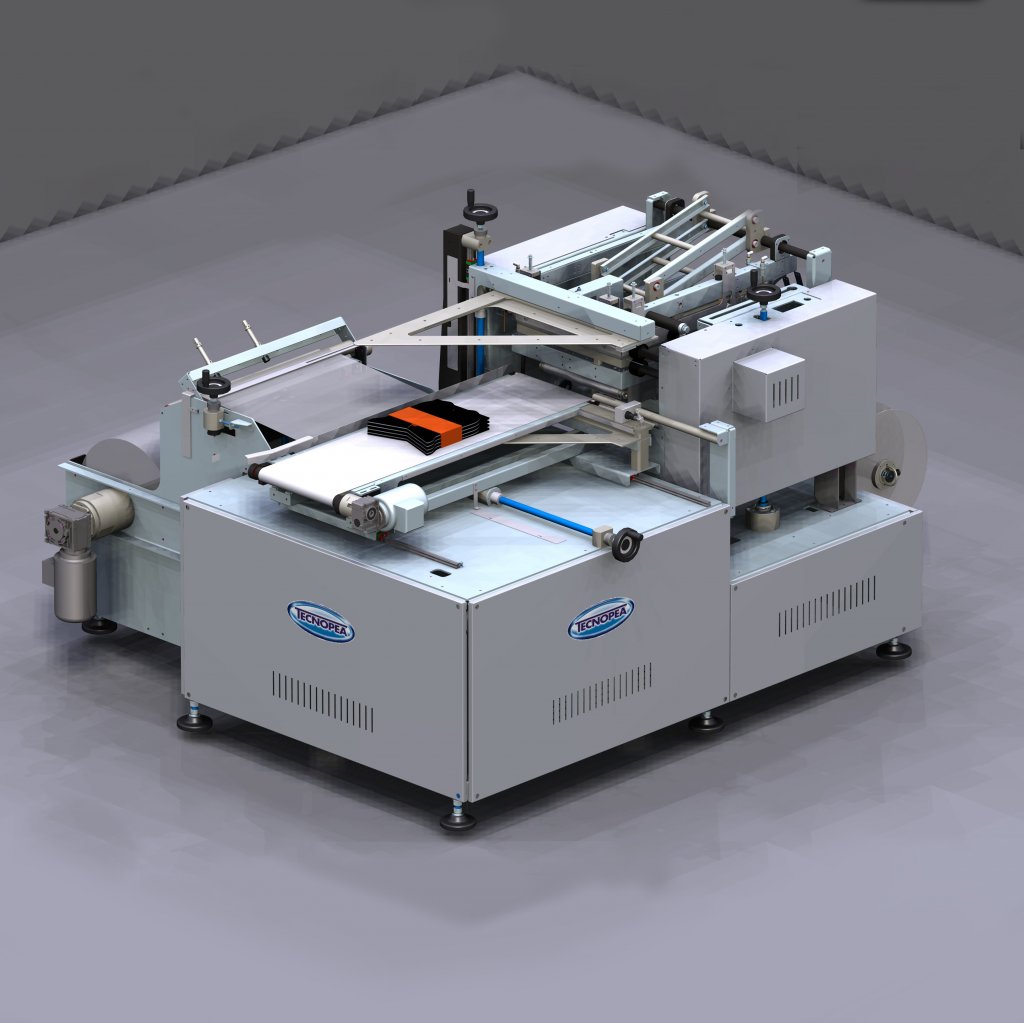

- Frame made of zinc-plated steel;

- PLC for the electronic control of all main functions of the boarding cycle;

- Electronic self-diagnosis with visualized errors or malfunctions;

- Touch screen display for the machine setting with the possibility to store in memory every single style;

- Robot for stockings transfer from transparent plastic forms to boarding forms;

- Positioning device to correctly align the waistband or welts to the proper size;

- Steam chamber with electronic pressure control up to 3 bar;

- Steam drying tunnel containing 6 pairs of boarding forms;

- Automatic stripping device with programmable stacking system on carousel and switch for faulty garments;

Data sheet

DIMENSIONS

4.850 x 3.350 x 3.050 (h) mm

WEIGHT

AIR CONSUMPTION

22 m3

CONSUMPTION INTERVAL

65 - 95 kg/hr

INSTALLED POWER

Potenza installata 7 kW - Potenza assorbita 4 kW

AIR PRESSURE

Pressione min linea vapore 6 bar - Pressione massima vapore in camera 3 bar

MIN. CYCLE TIME

6,5 Sec./1 pair

MAX PRODUCTION

550 pair/hr - 45 Dz/hr

BOARDING AND PACKAGING MACHINES FOR THE HOSIERY INDUSTRY

Would you like to be updated on Tecnopea news?