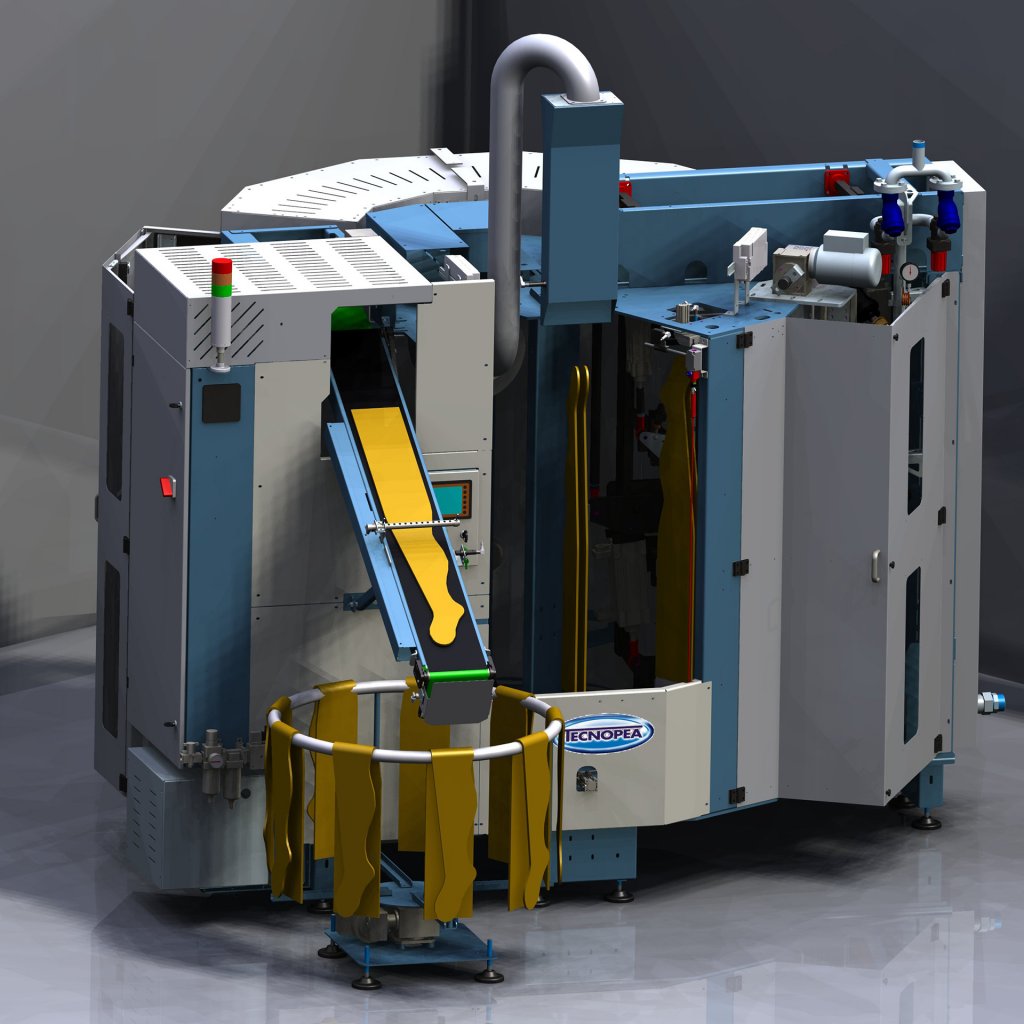

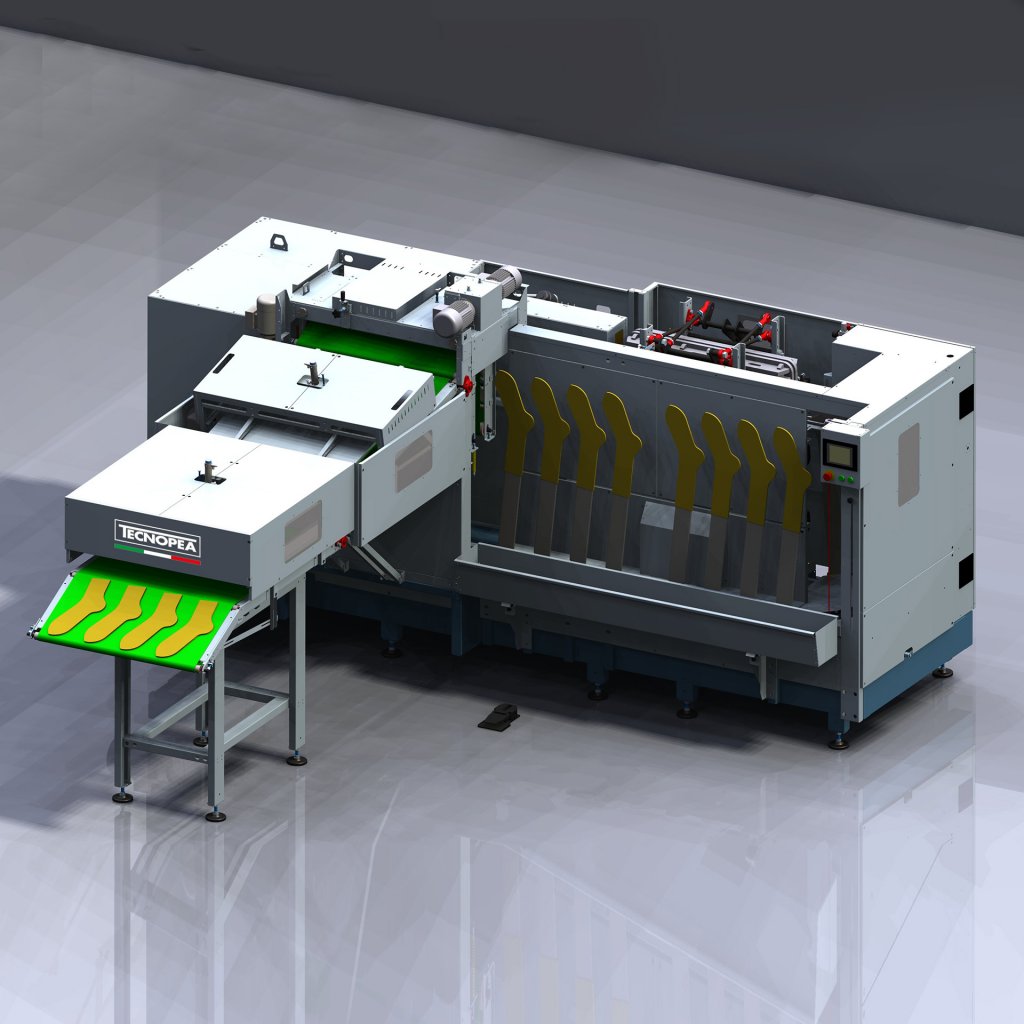

Smartfold + Smartbag

Automatic packaging line for stockings, knee-highs and pantyhose in polypropylene bags.

Automatic packaging line comprising of a garments folding system and a bagging machine.

Smartfold + Smartbag

Automatic packaging line comprising of an automatic folding module SmartFold connected to a bagging unit SmartBag. This system can be connected to the boarding machine or manually loaded from a dedicated conveyer.

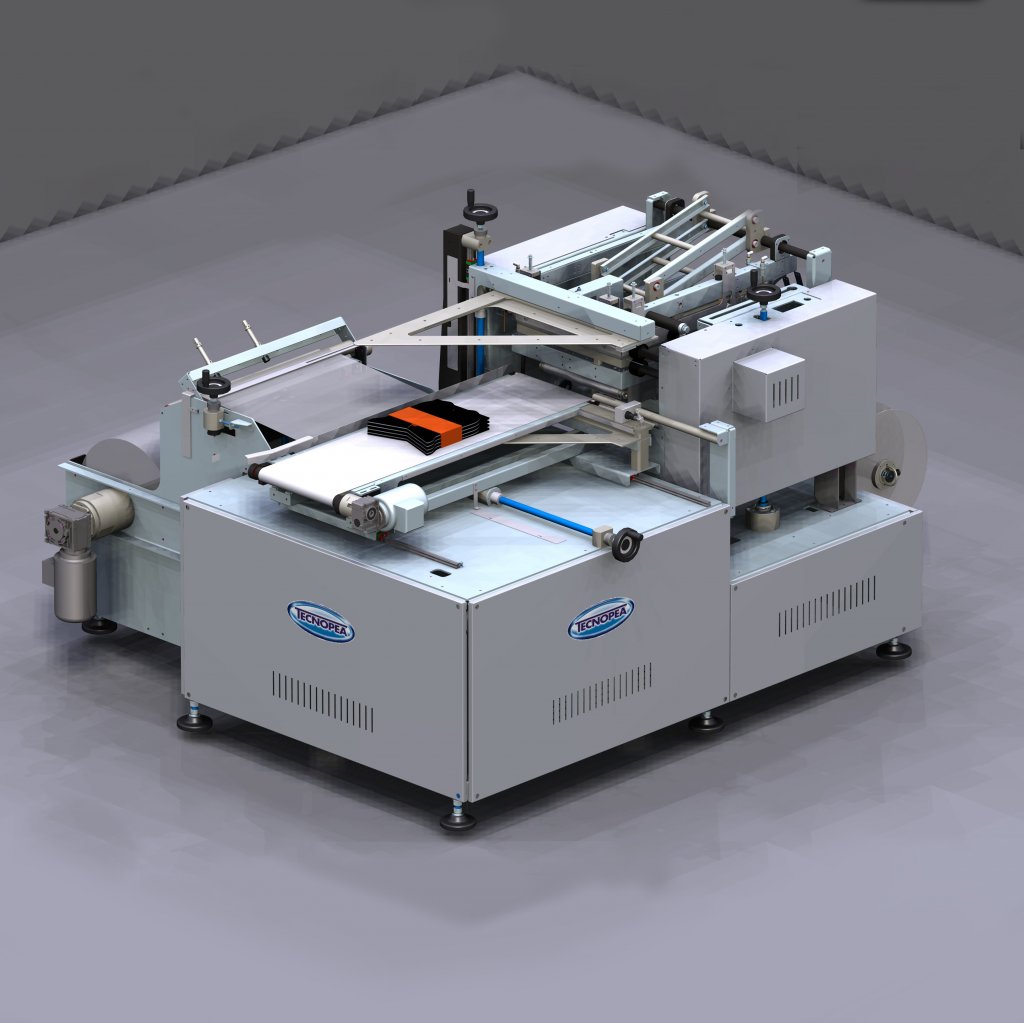

A servo-motor on each conveyer of the folding module allows a fine tuning of folding length for each individual style to store into machine memory. SmartBag has the possibility to adjust electronically the bag width to process different sizes. Machine can operate with V, C or L boards.

Features:

- Electronic folding settings;

- Bag closing with labels;

- Trimming device for flap corners;

- Option for pre-printed labels or for thermal printer;

- PLC for the electronic control of all main functions;

- Possibility to set all working parameters for each individual item;

- The system has an automatic diagnostic program with error messages and alarms;

- Touch screen for all machine settings;

- Device for 3rd flap closing on V-board;

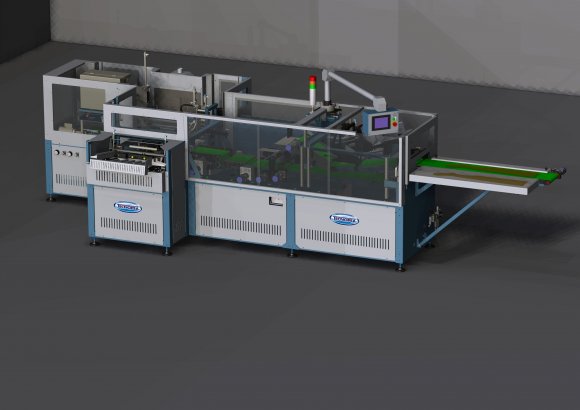

Optional:

- Triangle for the polypropylene film pre-folding;

- Mounting frame for the direct printer or for the label dispenser on the bags (front side);

- Label dispenser (front side);

- Thermal transfer printer for direct printing onto polypropylene;

- Heat stamping device with extractable fonts and ribbon.

Data sheet

DIMENSIONI

3.100 x 6.000 x 1.800 (h)

WEIGHT

2.000 Kg

AIR CONSUMPTION

278 Nl/min

CONSUMPTION INTERVAL

NSTALLED POWER

5 kW

AIR PRESSURE

6 bar

MIN. CYCLE TIME

5 Sec.

MAX PRODUCTION

60 Dz/hr

BOARDING AND PACKAGING MACHINES FOR THE HOSIERY INDUSTRY

Would you like to be updated on Tecnopea news?