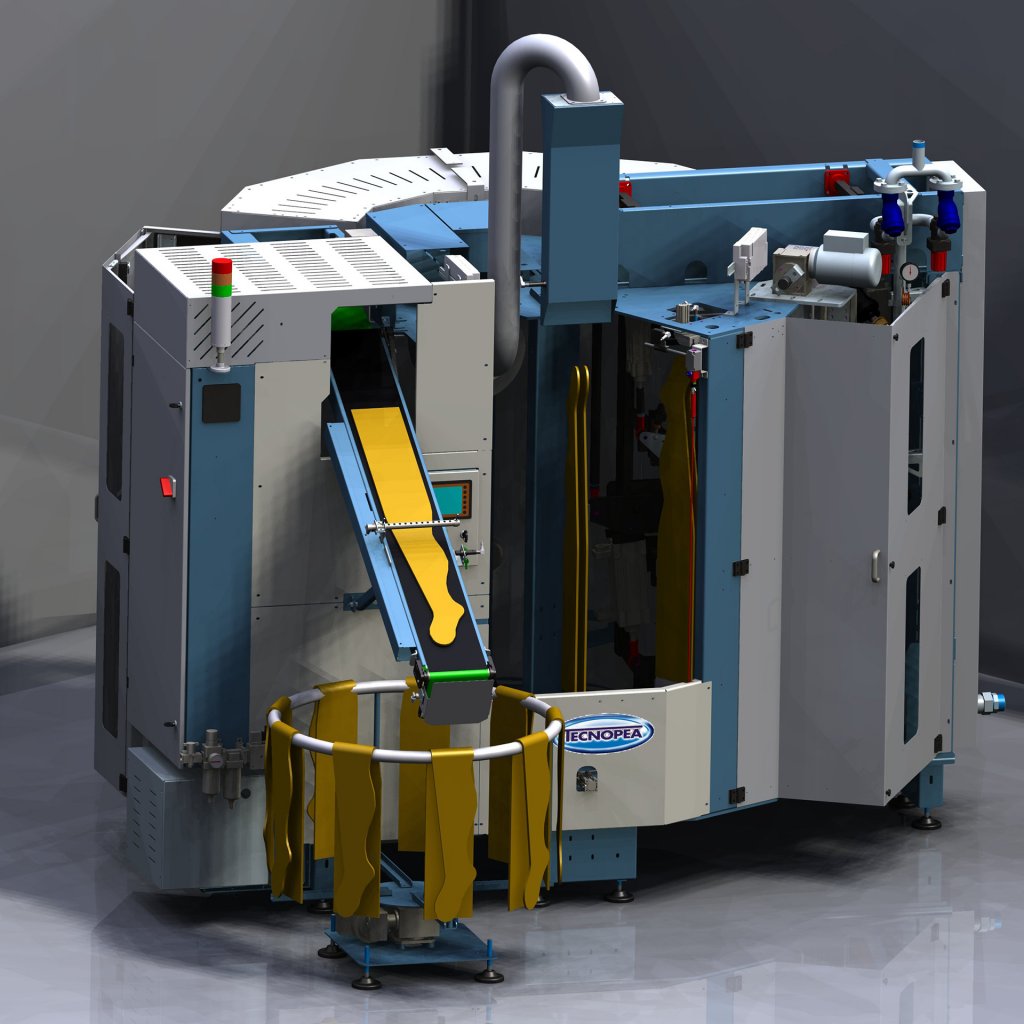

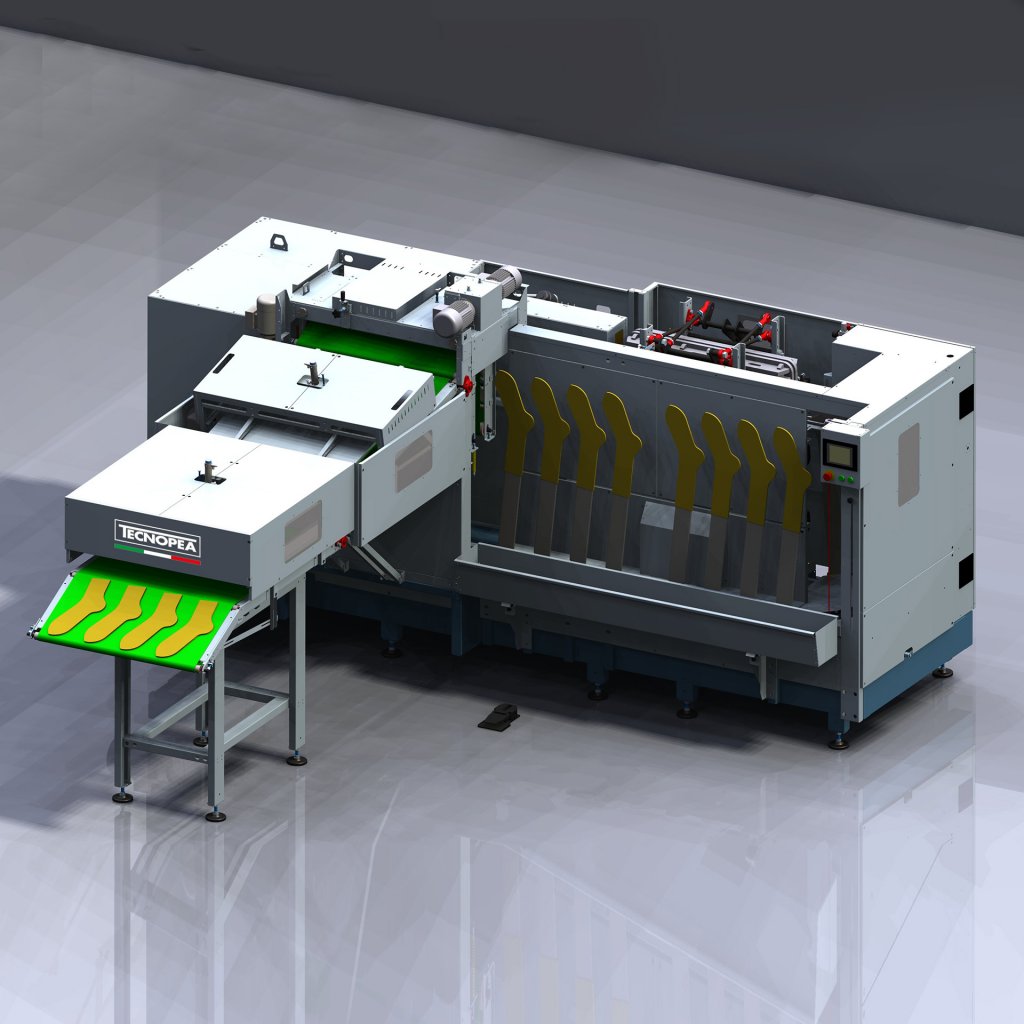

Ghibli 28

Steam boarding machine for socks.

Automatic steam boarding machine for men, women and children socks.

Ghibli 28

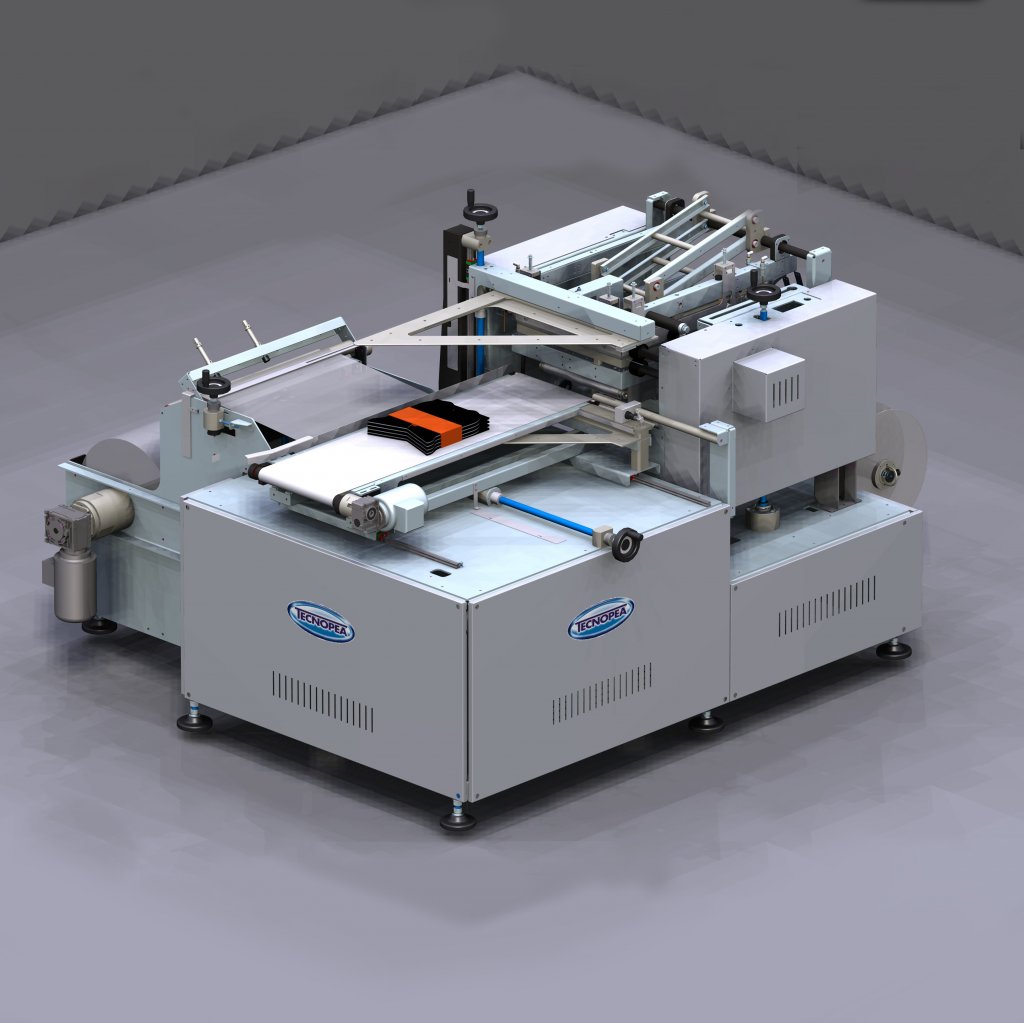

Direct loading of products on boarding forms by 1 or 2 operators allows the processing of a very wide range of styles and a very high productivity. The machine has a stripping device with clamps driven by a “brushless” motor and with a programmable stacking system that allows the simultaneous stripping of 2 socks. 24 boarding forms with patented profile and made up of special aluminum allow to process any type of fiber. The machine cycle provides the movement of 2 forms at the time with a longer processing time and a considerable quality improvement of products. The drying tunnel, perfectly insulated, is heated by means of a steam radiator with a very low energy consumption. A long drying time assure a high-quality boarding and a very high productivity up to 1.200 pairs/hour. Electric press with adjustable temperature just after the steam chamber, to reduce the moisture and flatten the socks. Steam consumption is measured over a period of time and its absolute values are subject to significant variations; we therefore recommend using a generator with a capacity of about 90 Kg/hr. The steam supply system must be equipped with condensate separators installed upstream of the connection to the machine and we also suggest the use of a pressure reducing valve adjustable up to 4 bar to avoid dangerous peaks. The drying tunnel, perfectly insulated, is heated by means of a steam radiator with a very low energy consumption. A long drying time assure a high-quality boarding and a very high productivity up to 1.200 pairs/hour. Electric press with adjustable temperature just after the steam chamber, to reduce the moisture and flatten the socks.

DIMENSIONS

3.610 x 3.575 x 2815 (h)

WEIGHT

AIR CONSUMPTION

7,3 m3 /hr

CONSUMPTION INTERVAL

25 – 55 kg/hr

INSTALLED POWER

8 kW

AIR PRESSURE

6 bar

MIN. CYCLE TIME

3 sec./1 pair

MAX PRODUCTION

1.200 pair/hr 100 Dz/hr

BOARDING AND PACKAGING MACHINES FOR THE HOSIERY INDUSTRY

Would you like to be updated on Tecnopea news?